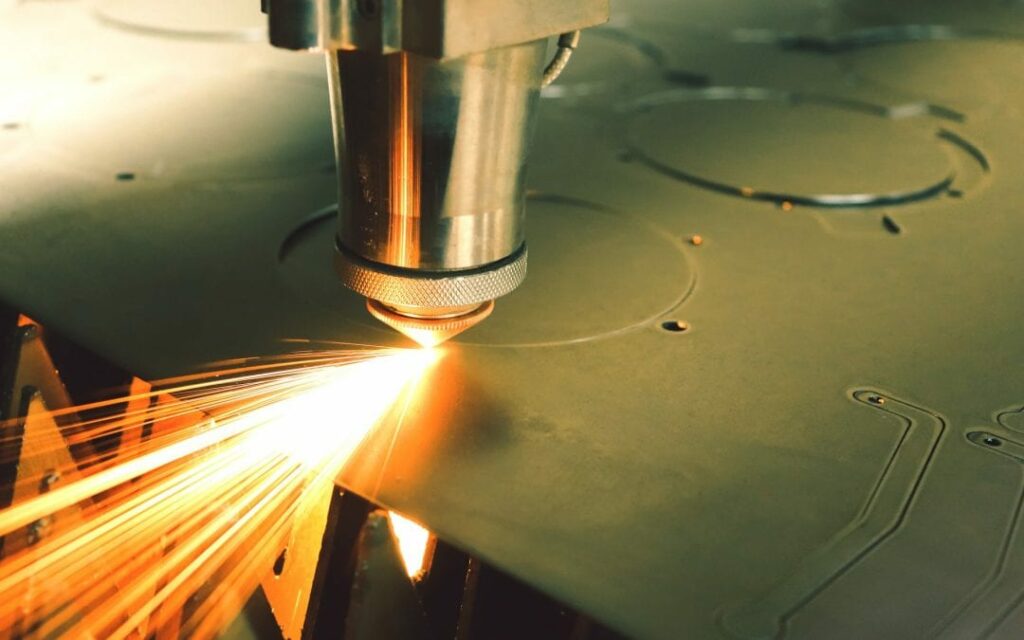

High Precision

Precision Manufacturing with tolerances as +/- 0.0002 in

Supplier Network

Diverse Production Supplier Network (5000+ Suppliers)

Industry Standards

High Quality (ISO 9001:2015, AS9100OD, ITAR, CWB, AWS)

If a part is not made to spec, we’ll make it right.

Precision Manufacturing with tolerances as +/- 0.0002 in

Diverse Production Supplier Network (5000+ Suppliers)

High Quality (ISO 9001:2015, AS9100OD, ITAR, CWB, AWS)

Within 24 to 48 Hours

Cost Effective Sourcing

No minimum Order Quantity

Meet all lead times set by customer

1000+ Material Options

100% Customer Fulfilment

© 2023 Specsquared Inc. All rights reserved. | Develop by Skuidtech.